No audio available for this content.

In the mission-critical world of aerospace and defense, where reliability and resilience can mean the difference between success and failure, precision timing is an essential technology for increasingly sophisticated and connected systems. Every nanosecond matters, whether ensuring UAVs operate safely or enabling secure real-time communication in high-threat environments. At the heart of these systems is precision timing technology, which ensures precise synchronization within and between systems, enabling high data throughput with minimal latency.

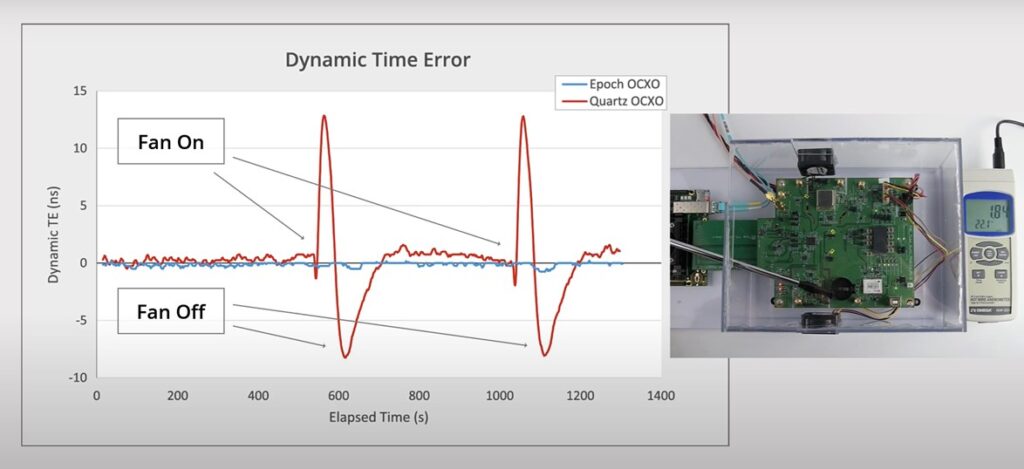

Aerospace and defense systems operate in some of the harshest environments on the planet, where extreme temperatures, shock and vibration and electromagnetic interference (EMI) are commonplace. While quartz technology has historically been used to deliver timing references in aerospace and defense applications, precision timing based on microelectromechanical systems (MEMS) technology has recently proven to be a superior alternative due to its better performance, resilience and reliability.

To understand the key differences between MEMS and quartz technologies for timing devices used in aerospace and defense applications, let’s focus on size, weight and power consumption (SWaP), as well as the ability of these two distinct types of timing technologies to perform reliably and accurately in harsh, demanding operating environments.

The Rise of MEMS Oscillators in Aerospace and Defense

MEMS-based precision timing technology is proven and highly reliable, designed to perform reliably in the harsh environments in which aerospace and defense applications operate. Unlike quartz timing devices, MEMS-based timing devices such as resonators, oscillators and clock generators are manufactured using semiconductor processes. This silicon MEMS technology enables unparalleled miniaturization, better resilience, and higher performance across a variety of environmental conditions. By encapsulating a MEMS resonator in a vacuum-sealed cavity, these timing devices are protected from contamination, aging, and environmental disruptions such as shock and vibration.

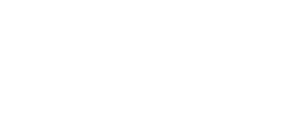

SiTime, a leader in MEMS-based precision timing technology, has developed a variety of MEMS-based oscillators and clocks that outperform quartz counterparts in key areas like stability, ruggedness, and SWaP. (See Figure 1.) These include popular devices such as temperature-compensated oscillators (TCXOs) and oven-controlled oscillators (OCXOs). The company’s MEMS-based Endura family of ruggedized Super-TCXOs and OCXOs, for example, is specifically designed for demanding aerospace and defense applications.

Key Advantages of MEMS Precision Timing Devices

- Low Phase Noise: MEMS Super-TCXOs deliver ultra-low phase noise, even in the presence of environmental stressors such as shock, vibration, and rapid temperature changes, which is essential for high-frequency RF systems such as tactical radios and satellite communication terminals. With low phase noise at 10 MHz output frequency of -165 dBc/Hz at 10 kHz offset and -175 dBc/Hz noise floor, these MEMS oscillators outperform typical quartz-based devices, ensuring cleaner signal transmission and better system performance.

- Shock and Vibration Resistance: MEMS oscillators are qualified by SiTime to the highest MIL-STD-883 shock stress level of 30,000 g and customers have reported they can operate at 100,000 g shock levels. This extreme shock resistance in conjunction with ultra-low acceleration sensitivity, as low as 0.009 ppb/g total gamma, make them ideal for rugged environments including space missions, aircraft and military vehicles. In contrast, quartz oscillators are prone to failure or frequency jumps under similar conditions.

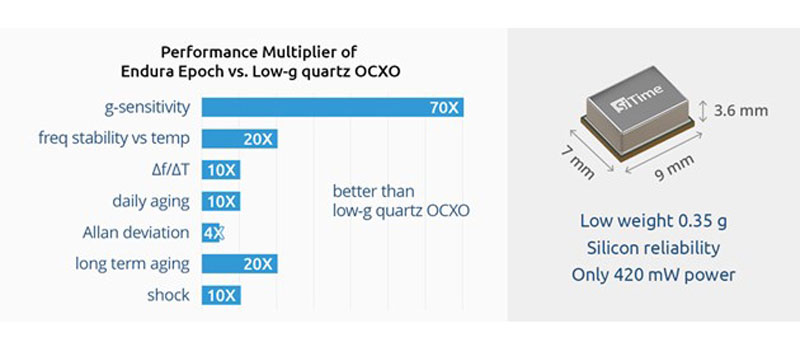

- Temperature Stability: Super-TCXOs exhibit excellent temperature stability, with frequency stability of ±10 ppb across a temperature range of -40 °C to +105 °C. This stability is critical for aerospace and defense applications subject to rapid temperature changes, which cause traditional quartz oscillators to fail or experience frequency jumps. (See Figure 2.)

- SWaP Efficiency: MEMS oscillators are significantly smaller, lighter, and more power-efficient than quartz devices, meeting the stringent SWaP requirements of modern aerospace systems. For example, OCXO-grade TCXOs (Elite-X) come in a compact 7.0 x 5.0 mm2 surface-mount package and consume less than 115 mW of power while delivering ±5ppb frequency stability over temperature performance. This makes them ideal for space-constrained, low-power applications like small satellites (SmallSats) and tactical communication systems.

- Reliability: MEMS oscillators offer superior long-term reliability, with a mean time between failures (MTBF) of more than 1 billion hours – about 30 times greater than quartz-based oscillators. Additionally, MEMS devices exhibit lower aging rates than quartz, ensuring consistent performance over extended missions.

Real-World Applications of Precision Timing Technology

- Tactical Radios: Precision Timing is critical for secure data transmission in military communication systems. Super-TCXOs, offering low phase noise and vibration resistance, ensure signal integrity even in the harshest battlefield conditions, improving the reliability of tactical radios used by defense forces.

- Satellite Communication Systems: Reliability, component size and power efficiency are paramount in satellite communications. MEMS oscillators enable high-bandwidth data transmission with minimal signal degradation, and their robust design ensures uninterrupted performance during mission-critical operations. Their small size and energy efficiency also make them ideal for space- and power-constrained satellite systems.

- UAVs: UAVs are often deployed in dynamic environments where they are exposed to extreme temperatures and vibrations. MEMS oscillators, with their superior shock and vibration resistance, are a preferred timing solution for maintaining stable navigation and communications, ensuring UAVs can carry out their missions without interruption.

- Radar Systems: Advanced radar systems depend on precise timing to synchronize signal processing, reduce interference, and optimize target detection. MEMS-based Precision Timing devices, with their high vibration resistance and temperature stability, deliver reliable performance in high-intensity environments, such as on naval vessels or fighter jets, where traditional quartz oscillators may struggle to maintain accuracy.

The Future of Precision Timing in Aerospace and Defense

As aerospace and defense systems become more advanced, the need for reliable precision timing solutions will continue to grow. MEMS-based oscillators, with their superior SWaP efficiency, rugged design, and inherent reliability, represent the future of Precision Timing technology in these critical sectors.

While quartz oscillators have served the aerospace and defense and industry for decades, MEMS technology is proving to be a more effective Precision Timing solution for next-generation systems. MEMS-based TCXOs and OCXOs are setting new benchmarks for Precision Timing, offering unmatched resilience, reliability, and performance in the most demanding environments.