No audio available for this content.

Advanced Navigation has successfully demonstrated a breakthrough in underground navigation, delivering high-precision positioning without reliance on fixed infrastructure or GNSS.

The demonstration of the company’s Hybrid Navigation System was livestreamed from the Pyhäsalmi Mine in Pyhäjärvi, Finland, as part of the Deep Mining Open Call under the Think and Act Differently program sponsored by BHP, an Australian mining and metals corporation.

The Deep Mining Open Call, launched in September 2024, sought innovators with capability that could be applied to deep underground mining. The focus was on addressing challenges such as high temperature, high rock stress, and hyper-saline conditions in deep mining environments. The inactive Pyhäsalmi mine has the harsh conditions and depth required for the technology test.

Based in Australia, Advanced Navigation was selected from more than 90 global applicants to demonstrate its technology.

Positioning Challenges

Navigating the vast subterranean network of the Pyhäsalmi Mine posed significant challenges. The mine is situated just two degrees below the Arctic Circle, where traditional systems fail. Located 1.4 km underground at a latitude of 63°, it is completely impervious to GNSS signals. Its repetitive, multi-level tunnel network creates a high risk of visual disorientation, while its metallic ores distort magnetic fields and scatter radio waves.

To overcome these conditions, mines typically rely on infrastructure-heavy solutions such as ultra-wideband beacons, Wi-Fi, 5G repeaters or perception-based techniques such as simultaneous localization and mapping (SLAM), which require cameras. These methods are costly to integrate and maintain, slow to install, and often unavailable in hazardous or unmapped zones where reliable navigation is critical. Shifting to a resilient navigation system with less dependency on infrastructure offers a scalable alternative, enabling reliable navigation even in environments considered hazardous or inaccessible.

System Architecture

Advanced Navigation’s Hybrid Navigation System demonstrates long-range, infrastructure-free, real-time navigation in a deep, GPS-denied environment. The system combines a laser velocity sensor (LVS) with the Boreas D90 fiber-optic gyroscope inertial navigation system (FOG INS).

FOG INS. The Hybrid Navigation System is centered on the Boreas FOG INS. Unlike conventional systems, Boreas doesn’t rely on GNSS or magnetic compasses. Instead, it uses ultra-sensitive FOG technology to detect the Earth’s rotation and determine true north, a process known as gyro-compassing, to find the vehicle’s heading.

For the test, the Boreas D90, along with various additional equipment providing power, networking and logging capabilities, was secured inside the vehicle.

LVS. To maintain and enhance this accuracy, the INS is fused with Advanced Navigation’s LVS. Using infrared lasers, LVS continuously measures the vehicle’s true 3D velocity relative to the ground. This real-time data is critical for correcting the gradual drift that occurs in standalone inertial systems, enabling the hybrid system to maintain precision over extended distances.

The LVS sensor features two components: an external, passive optical head, and an active sensor body. The optical head is primarily responsible for rigidly holding the alignment between the three telescopes. The sensor body houses the active photonics system, laser and processing system.

Because pre-production hardware was used for this test, three discrete fiber-optic cables were used to connect the externally mounted LVS optical head to the LVS sensor inside the vehicle. Production hardware will include a single, IP69K rated optical-fiber cable that connects the LVS sensor body to the IP69K rated optical head.

The LVS optical head was attached to the trunk of the vehicle using a suction cup to provide a clear line of sight from each telescope to the terrain. A GNSS antenna was attached to the roof in the same manner. Coaxial cable connected the GNSS antenna to the Boreas D90.

Fusion Software. The system integration relied on the company’s AdNav OS Fusion software. Using adaptive algorithms, OS Fusion dynamically weighs the reliability of each sensor in real time.

Together, these technologies form a resilient hybrid system delivering precise, uninterrupted navigational data in extreme environments, without GNSS or fixed infrastructure, the company said.

“We were thoroughly impressed by the results the sensor fusion provided,” said Magnus Zetterberg, senior consultant at Combitech, who observed the demonstration. “I have used and been exposed to these sorts of sensors in other projects, and nothing has come close to this level of performance. It’s clear the Laser Velocity Sensor is a major key in providing these outstanding results.”

Proven in the Depths

A one-time surface calibration using real-time kinematic GNSS aligned the LVS and INS frames on the vehicle, a Mercedes-Benz V-class. After the calibration, the trials were unaided within the underground environment.

Two different test scenarios were conducted: a surface-to-surface test, and an underground loop test. Validated across five separate runs in isolation from external aids or maps, the Hybrid Navigation System repeatedly achieved an accuracy of better than 0.1% of distance traveled — demolishing a barrier once considered fundamental to underground navigation.

Without relying on any fixed positioning infrastructure, pre-existing maps or external aiding, the tests achieved consistent sub-0.1% navigation error across multiple runs.

Surface-to-Surface Runs

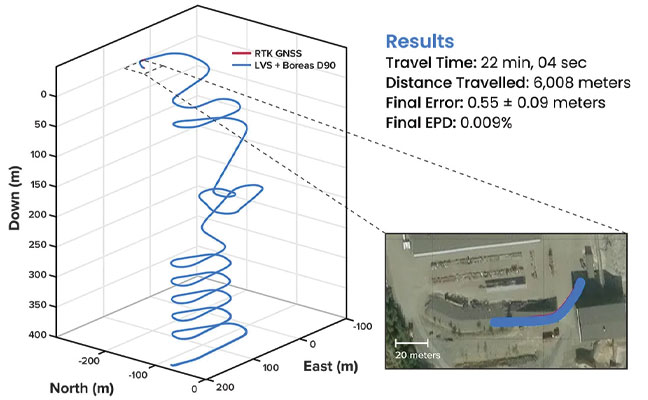

Runs 1, 2 and 3 – 400 m. To demonstrate the system’s repeatability and accuracy, three identical runs were conducted to a depth of 400 meters. Each run involved an approximate 3 km one-way traverse for a full 6 km loop. The results highlight the system’s consistent performance during underground operation, with a mean final position error of 2.83 ±0.09 meters, representing 0.047% of the total distance traveled.

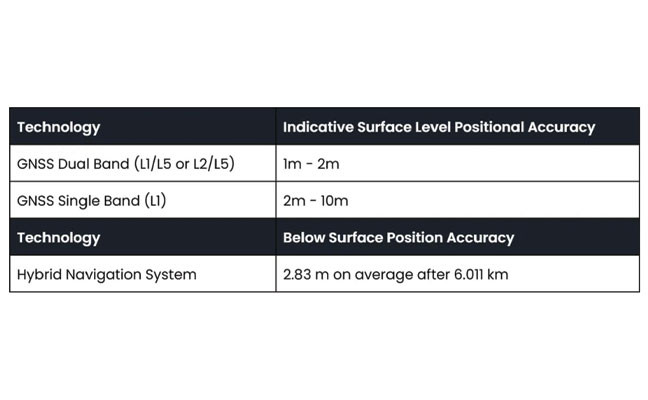

Over the 6 km rough and rugged terrain that extended 400 m below the surface, the system achieved a best-case 3D position error of 0.55 m (0.009%), with an average error of 2.83 m (0.047%). For context, standard single-band GNSS on the surface typically delivers 2–10 m accuracy in open-sky conditions. The system delivered significantly greater precision even within a subterranean labyrinth. FIGURE 1 present the key performance metrics for these runs. FIGURE 2 shows reacquisition of GNSS signals upon exiting the mine.

“We’ve worked in underground environments for decades. Seeing this level of precision achieved on the first run signals huge potential for safer and more efficient underground vehicle operations,” said Olli Mylläri, vice president of technology at Normet, a mining technology company.

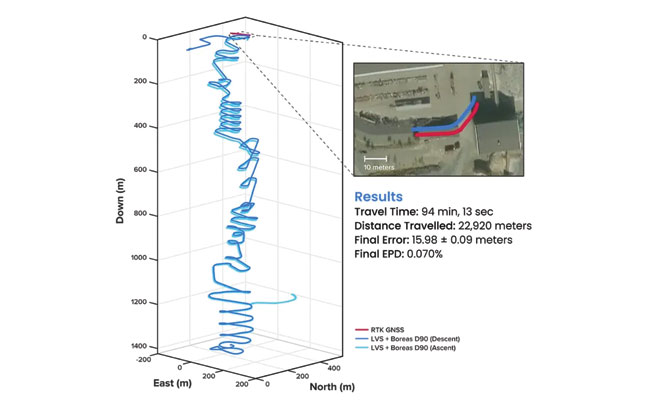

Run 4 – 1,400 m. To evaluate the system’s performance over an extended distance, a single run was conducted to the deepest accessible point of the mine, reaching a depth of 1,400 m. The system navigated the 22.9 km route — the equivalent of a half-marathon — in total darkness.

The final position error was 15.9 m (0.07%), showcasing its immunity to the drift that plagues other inertial systems. This extended traverse, lasting more than 94 minutes, also included a deliberate stationary period at the bottom before the return to the surface. The performance of this deep run is detailed in FIGURE 3.

Entirely Underground

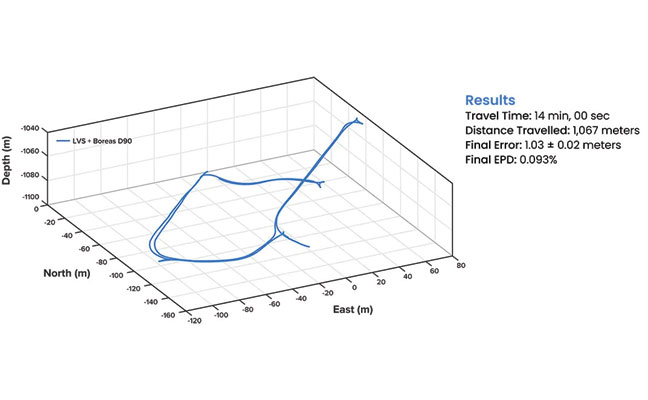

Run 5 – 1,067 m. A single run of 1,067 m was conducted over a period of 14 minutes. Without relying on magnetometers or external aids, the system determined heading using its built-in gyrocompassing procedure, measuring the Earth’s rotation to establish true north. It then navigated a 1 km course with just 1 meter of error, demonstrating its capability for rapid deployment in the most challenging and unfamiliar terrain. See results in FIGURE 4.

1,067 m, with a measured final error of 1.03 ±0.02 m, yielding an error per distance traveled of 0.093%.

While additional testing was planned to further validate the results, time constraints limited this study to a single test. The findings provide a representative indication of system performance under the tested conditions. TABLE 1 shows a comparison to GNSS navigation.

Scalable Autonomy

While mines will continue to use fixed infrastructure, this technology significantly reduces dependency, enabling resilient, high-precision navigation in previously inaccessible or unmapped areas. This performance marks a step change in underground navigation, unlocking new potential for fleet management, predictive collision avoidance, material tracking and scalable autonomy across mining operations.

“At Normet, we specialize in advanced solutions for underground mining and tunneling, so we know firsthand how difficult accurate and reliable navigation can be in these environments,” Mylläri said. “Seeing Advanced Navigation’s Hybrid Navigation System deliver consistent positioning with minimal infrastructure deep within the Pyhäsalmi Mine was remarkable. It’s a powerful step forward for automation and safety in the underground space.”

In today’s dynamic operational environments, relying on a single navigation technology is no longer viable. Robust navigation demands a layered, inertial-first and multi-sensor architecture — held together by intelligent software — that can adapt and scale to meet the unique demands of each operation.

“Ultimately, this vehicle-based, inertial-centered architecture provides the resilient foundation required for the mining sector to achieve its long-term goal: efficient autonomous ore extraction at depths hostile to human activity,” Vandecar said.

“Unreliable navigation underground isn’t a minor technical constraint — it’s a major operational bottleneck,” said Joe Vandecar, senior product manager, Advanced Navigation. “Maintaining precision over a 22.9 km subterranean course in Europe’s deepest underground mine demonstrates a level of performance that few systems in the world can rival without any prior intelligence of the environment. These results prove we’re one step closer to unlocking scalable underground autonomy.”

The Hybrid Navigation System is set for commercial release later this year.

Adapted from a paper authored by Patrick Wiltshire, David McManus, James Spollard, Mark Gibson, Matthew Suntup, Tim Laws and Lyle Roberts. The full paper is available on the Advanced Navigation website (advancednavigation.com).