Trimble expands machine control system for wheel loaders

Trimble has introduced version 12.81 of its Trimble GCS900 Grade Control System. The new version further expands the mix of machines supported to now include wheel loaders, demonstrating Trimble’s continued commitment to meet the contractor’s needs for construction technology across a mixed fleet and for all phases of the project life cycle.

“Trimble GCS900 version 12.81 means big productivity gains for contractors who operate wheel loaders,” said Ryan Kunisch, marketing director for Trimble’s Civil Engineering and Construction Division. “We have seen up to a 40 percent increase in productivity for material placement and grading activities and typically a 25 percent reduction in undercutting when the GCS900 system is used.”

version 12.81 means big productivity gains for contractors who operate wheel loaders,” said Ryan Kunisch, marketing director for Trimble’s Civil Engineering and Construction Division. “We have seen up to a 40 percent increase in productivity for material placement and grading activities and typically a 25 percent reduction in undercutting when the GCS900 system is used.”

The new configuration for wheel loaders allows contractors to realize productivity gains in both fine and rough grading applications. Operators can precisely control the amount of material being graded, improve fine grading accuracy and time, and reduce the potential for undercutting the surface during material placement or removal.

Using a wheel loader equipped with GCS900, contractors can track material weight with a Trimble LOADRITE weighing system. In addition, material placement and grade can be monitored by adding a VisionLink Project Monitoring subscription for a more accurate and complete picture of project progress.

Features of GSC900

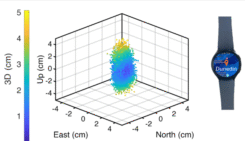

- Uses two GNSS receivers and solid state angle sensors and an inertial measurement unit (IMU) to measure the precise 3D position of the bucket

- Tracks GPS, GLONASS and Galileo signals

- Quickly performs complex tasks and simplify finishing slopes with accurate 3D positioning

Follow Us